About Us

About Gokul Metal & Alloys

Gokul Metal and Alloys, founded in 2000 by Dr. A. Subramani, is a proprietorship firm committed to sustainable growth and environmental stewardship. With an annual recycling capacity of 8,000 metric tons of aluminium, we specialize in environmentally responsible processes that deliver value-added solutions to the industry. Our facility spans 87,000 sq. ft, nestled within nature and highlighted by a 15,000 sq. ft. landscaped garden, reflecting our dedication to ecological harmony. We are proud to be one of the fastest-growing aluminium recyclers in the Indian market, known not only for our production capabilities but also for our proactive approach to environmental care. At the heart of our operations is a state-of-the-art pollution control unit, designed to purify fumes and ensure a clean, pollution-free working environment—underscoring our belief that progress and sustainability go hand in hand.

Celebrating 25 Years of Excellence in Aluminium Innovation

Founded in 2000 in Coimbatore, Tamil Nadu, by the visionary duo

Mr. S.M. Arumugam and Dr. A. Subramani, GOKUL METAL & ALLOYS has proudly completed a remarkable journey of 25 years in the aluminium industry. From the very beginning, our mission has been to deliver top-quality aluminium alloy ingots while preserving the environment through sustainable recycling practices. Guided by continuous research and development, we’ve become a trusted name in eco-conscious manufacturing, producing aluminium ingots that stand as benchmarks of quality and reliability. As we celebrate this silver jubilee in 2025, we honor our legacy of innovation, commitment, and excellence—and look forward to a future built on the same enduring values.

25

Years of

Experience

info@gokulalloys.com

+91 88700 15097

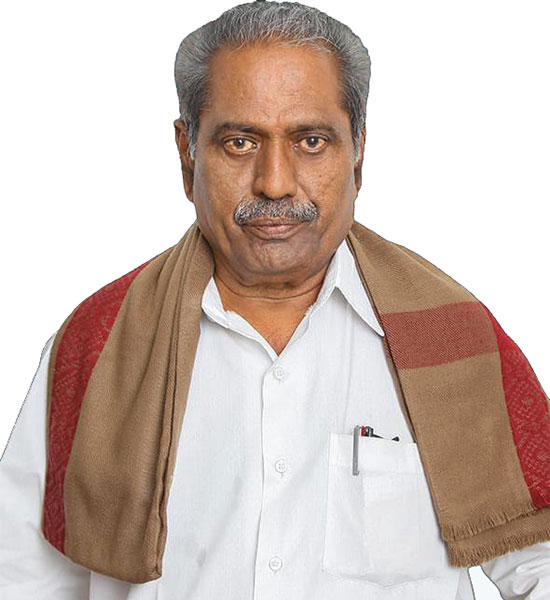

Mr. S.M. Arumugam

Founder

Dr. A .Subramani

Properitor & CEO

Mrs.S.Nagalakshmi

President (Sales and Marketing)Our Vision

At Gokul Metal and Alloys, we are committed to delivering the highest quality aluminium ingots, recognizing their critical role as the foundational components in the production of automobile parts. We believe that precision, consistency, and purity in every ingot directly contribute to the excellence and durability of the end product. Our vision is to set the benchmark for quality in aluminium recycling—minimizing rejection, maximizing performance, and driving innovation in every melt.

Our Mission

At Gokul Metal and Alloys, our mission is to double our aluminium recycling capacity by 2030, strengthening our role in building a more sustainable and technologically advanced future. We are dedicated to integrating next-generation technologies into our operations and fostering a culture of excellence, innovation, and integrity. Through continuous improvement and unwavering dedication, we aim to contribute meaningfully to India’s industrial growth and environmental resilience.

With over two decades of deep market insight, Mrs. S. Nagalakshmi has been a transformative force at Gokul Metal & Alloys. Her dynamic approach to sales and client development has empowered the company to expand its customer base exponentially—achieving a remarkable tenfold growth. Her strategic exploration of Just-In-Time (JIT) management practices reflects her commitment to operational excellence and corporate client satisfaction. Through innovation, persistence, and unwavering dedication, she continues to chart new paths for sustainable business growth..

Quality Objectives

To constantly upgrade the technology and pursue continual improvement project by practicing latest techniques to achieve higher goals.

To encourage team work through employee awareness, training and motivation.

To establish our distinct identity in markets.

Production Capacity

Aluminium melting oil fired hydraulic tilting furnace in 600Kg capacity with automatic Ingots mould conveyor.

Aluminium melting oil fired rotary Furnace in 2.8 MT capacity with automatic Ingots mould conveyor.

Aluminium Dross Processing Machine.

28MT/day Production Capacity.

Company Profile

Year of establishment 2000.

Ownership Type - Properitorship

Major Markets - India.

Team & Staff

Total Employees – 98 People

Managerial Staffs – 3 people

Research/ QC Staff - 4 People

Skilled Staff - 15 People

Skilled Workers - 16 people

Semi Skilled Workers - 40 people

Loading & Unloading workers - 20 people

Packaging & Shipment

Own Vehicles are available for transportation.

Gradewise packing through strap

Material loading using Crane

Weighing Machines Available in 1 , 2 , 60 tons and 500 kg’s.

Skilled workers in packaging and loading

Shipment Mode by Road.